Models 1949 and 1956

Postwar life of Panzerfaust

In 1945, in the context of further development of tactics and military doctrine based on the experience gained by the end of WWII , the Yugoslav Army faced the challenge of successfully defeating the enemy armor attacks in the battefield at short ranges. Due to lack of armor and antitank weapons, the Ministry of National Defence had to look into the German antitank tactics of 1942-1945. The antitank combat concept was based on the mass use of cheap light antitank weapons by infantry units, viz. the man-portable, shoulder-launched anti-armor weapons that fire the overcaliber HEAT warheads. Virtually, the German ”Faustpatrone” (fist cartridge) and ”Panzerfaust” (armor or tank fist)recoilless grenade launchers became predecessors of the new Yugoslav portable antitank weapon.

To implement the new adopted concept, the approved Plan of Weapons Industry and Shipbuilding for 1947-1951 among other things provided for production of “the AT armor fist” (hand-held AT grenade launcher). According to the Plan, the Kragujevac Arms Factory (Enterprise Crvena Zastava) besides new small arms production lines was to launch a separate line for production of the 7.9-mm Mauser rifles and hand-held AT grenade launchers (RB, Serbian: Rucni Bacac).

Unfortunately, the planned launch of both production facilities had turned out to be hardly feasible. Pilot production of the RB (RPG) grenade laumcher was expected in 1947-1948, while commercial production – in 1949. Totally the armed forces were to receive 100,000 grenade launchers in 1949, and 150,000 grenade launchers in 1950 and 1951 each. But in the course of the Soviet-Yugoslav crisis (June 28, 1948), the Kragujevac Factory found itself in the position when it had to use only one joint line for production of all weapons, including the Mauser rifles and grenade launchers. Besides, Crvena Zastava, Institute #11 and Arms Department of the Military-Technical Institute lacked experienced staff to design this type of weapon. Therefore, production of the RB grenade launchers was shifted to the Military Factory in Valjievo (the Krusik Enterprise) that retained its facilities and experienced staff, experts in shells, fuzes and hand grenades. The production team was led by Anton Mesicek, Chief of Design Bureau. Mesicek started his design efforts on the hand-held AT grenade launcher and respective warhead modelling after German Panzerfaust 30 (Pzf 30) as far back as 1946. It was expected to design and develop a multishot grenade launcher (whereas, Faustpatrone was a single-shot weapon) that would have a high rate of fire, long sight distance and high penetration of the HEAT warhead.

Initially, the design efforts were focused on development of the overcaliber HEAT grenade with flexible fins (the fin assembly consisted of a launch tube and four unfolded fins), and the hollow-charge body. At the first glance, such solution was a little different from German Panzerfaust 30. The grenade consisted of an assembled warhead containing of a HEAT charge and cavity, and a tail unit with a fuze, primer and fin assy. The tail unit had a wooden shaft with four thin steel blades (fins). On Septemble 27, 1948, engineer Buklis designed and Mesicek approved “hand-held AT grenade launcher ‘’Bullet’’ – fin assembly”. The grenade was 552.5 mm long. The wooden shaft was 43.7 mm in dia. The shaft had four thin steel fins. Eventually, the drawing of “Fuze TK 12” used to develop the fuze without safety lock K-301, was finalized on July 28, 1949.

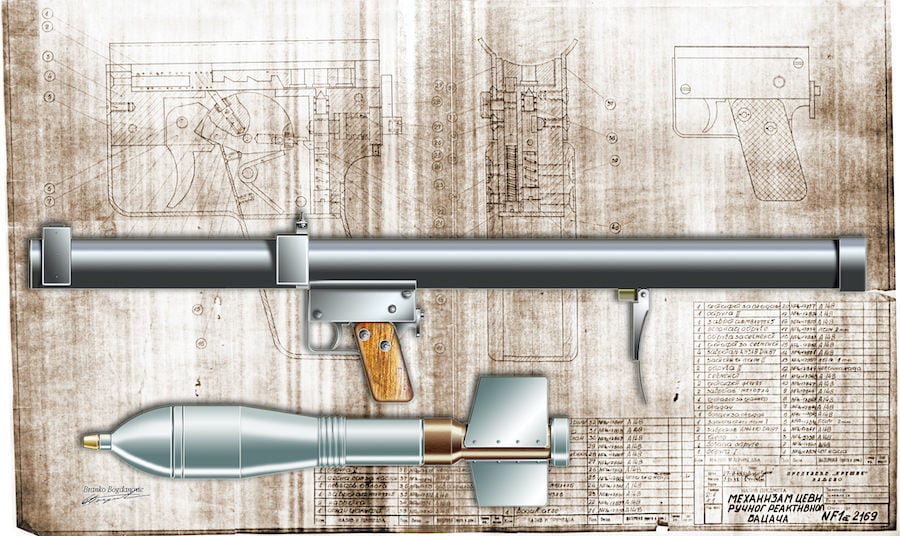

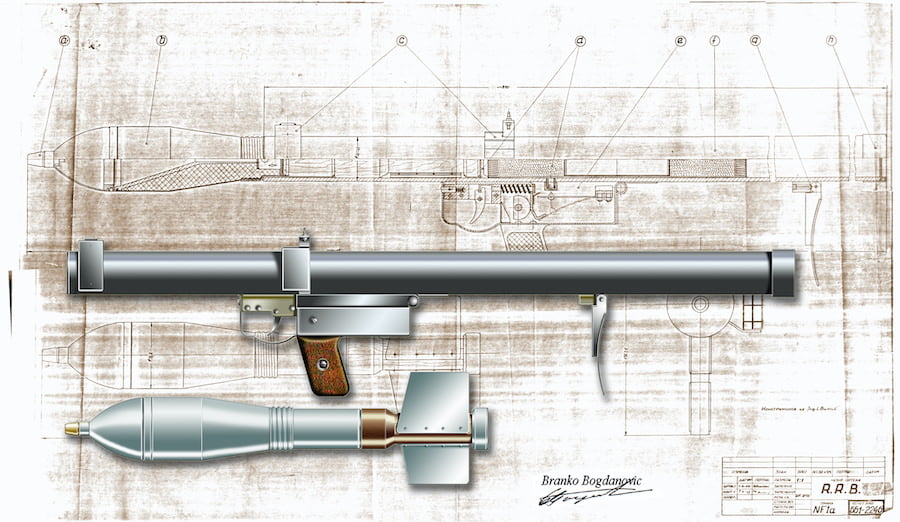

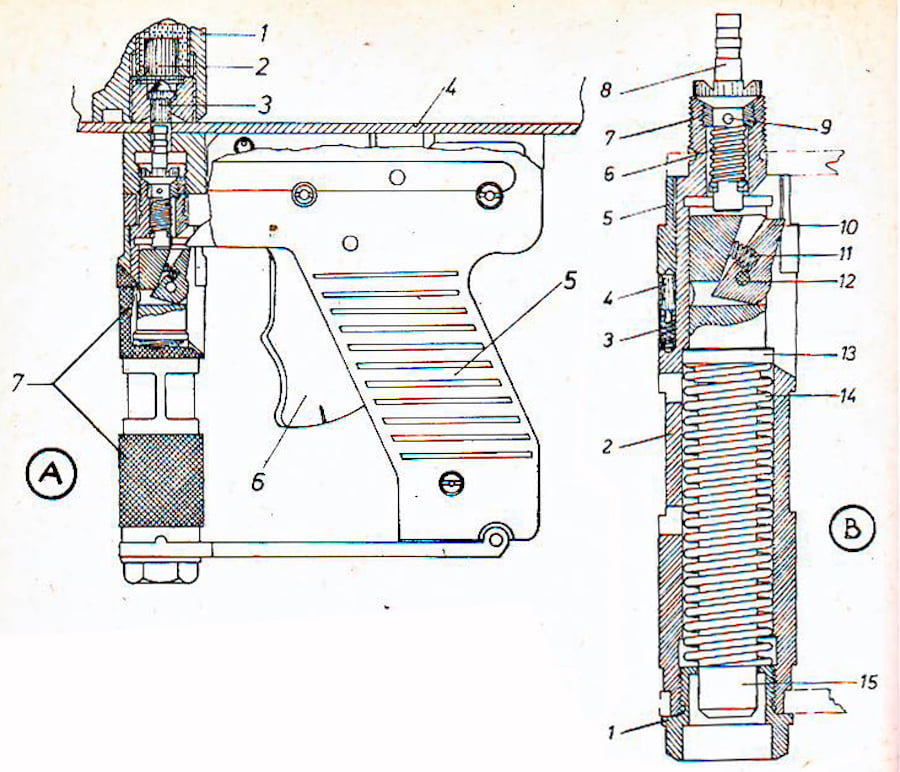

Following a decision to combine “the 90-mm HEAT warhead with the hand-held AT grenade launcher, model 1949” (RRB M49), Mesicek started designing the hand-held AT grenade launcher itself. Initially he designed a smooth-bore seamless steel tube (barrel) of 970 mm long, 44 mm in caliber. The barrel carried a firing mechanism with a safety lock and firing pin unit, as well as a receiver with a sliding bolt, and a small-bore rifle trigger, pistol grip with wooden side plates, magazine case and magazine release mounted between the grip and trigger guard, and a detachable box-type single-line magazine for 6 rim-fire blank cartridges, 5 6 mm in caliber (used as primers). The cartridge chamber was connected with the priming hole through a tube. The firing pin ignited the blank cartridge that burnt through the cardboard cartridge case and ignited the gunpowder used as the propellant charge. The safety lock looked like a safety rod sliding left and right to lock/unlock the trigger. The effective range was 200 m, maximum firing range was 600 m, HEAT warhead penetration varied from 100 mm (Model 1949) to 240 mm (Models 1950 and 1951). The grenade launcher had an optical sight to successfully defeat the targets at a distance up to 200 m, plus a metal sight and shoulder piece. The weight of the hand-held grenade launcher was 6200 g, combat rate of fire – 3 rounds per minute, warhead muzzle velocity – 87 mps.

The propellant charge was placed into a cardboard cartridge case, one end of which was blanked-off with a rubber gasket. The case contained the gunpowder charge (420 g) and sand batch separated with a cardboard membrane (the sand was used to boost the gas pressure).

Simultaneously an alternative design of “the hand-held rocket-propellant grenade launcher mechanism (and) barrel” (June 27, 1948, NF1ā 2169) was under consideration. The mechanism of this grenade launcher was fed from the 3-cartridge single-line steel magazine mounted on the receiver rear section.

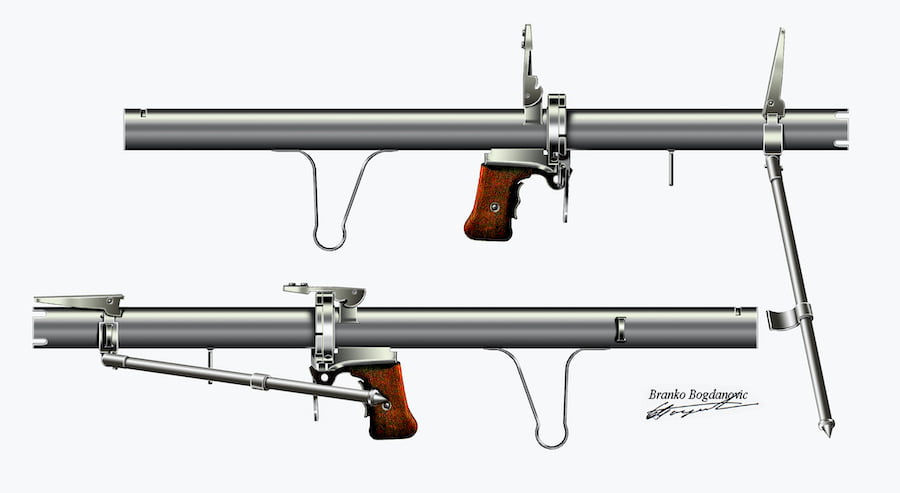

But the YPA General HQ board had selected the Mesicek hand-held AT grenade launcher with the sliding bolt, coded RRB. Production of the RRB M49 grenade launchers was set up in Kragujevac enterprise Crvena Zastava, while production of the HEAT warheads (grenades)– in Valjevo enterprise Krusik. A prototype and several dummy RRB M49s had been made for the military parade of May 1, 1948. In 1949, the Kragujevac factory produced the first batch of 232 hand-held AT grenade launchers. However, by that time several design drawbacks had been recorded – expensive and sophisticated production processes, low engagement accuracy, jams, and slow muzzle velocity. Mesicek had updated (and modified) the weapon. These measures had simplified the commercial production. The modifications included shoulder sling attachments soldered to the barrel, simple metal sight and shoulder piece soldered (instead of ring-mounted) to the barrel, modified and improved shape of the pistol grip and safety lock knob, improved optical sight.

The Krusik factory had developped in May 7, 1949 another shingle-shot firing mechanism design – the firing mechanism together with the pistol grip was turned down in the vertical plane through 90 deg to arm the plate firing pin spring. The cartridges were loaded in the chamber one by one. But this version had been rejected since it was worse than the Mesicek solution.

The RRB M49 grenade also had drawbacks – inadequate penetration (less than that of German Panzerfaust), high rebounding, K-301 fuze failures as the target impacted at an angle other than 90 degrees. On May 23, 1949, the Krusik team started designing “the RRB Grenade, Group B” with a shaft made of Silumin, i.e. the Silicon/Aluminum alloy. On February 13, 1950, the team successfully fulfilled the project of “the AU4 HEAT warhead fuze”, coded K-302. The improved grenade was produced under designations RRB M50 (with old fuze K-301) and RRB M51 (with new fuze K-302 and 610 g of TNT/RDX HE charge). Production of flexible unfolded metal fins, cavity, body and nose cone became a separate problem. Since the Kragujevac and Valjevo factories had no time to master their production, it was contracted to enterprise EMO (former Western) in Cele (Republic of Slovenia). Crvena Zastava proceeded with commercial production of “the modified grenade launcher” RRB M49. In 1950 the Yugoslav Army received 6625 grenade launchers, in 1951 – 3437, while in 1952 – 20 (only). It was the year when it was established that the majority of the drawbacks had failed to be rectified. Besides, simultaneously new more rigid specifications were developed for the hand-held AT grenade launchers. It became evident that the best option was to adopt a new RPG development concept.

On the other side, before 1953, the Yugoslav Army under “Military Assistance Agreement” with the USA received 1000 modern 60-mm light antiarmor weapons (LAW) Bazooka M9 and M9A1 caliber 89 mm (3,5”). Since it was expected that the Army would receive many Bazookas M20, it was planned that the national industry would be converted to production of the 3.5’’ rocket-propellant grenades with fuzes BD-M404A1 so that within the period of 1955-1964 the army needs in this type of weapon would be satisfied. Such situation boosted development of the national weapon. The designing efforts on such antitank weapon more lethal than RRB M49 lasted since 1952 until 1957. However due to the inconsistent policy, the YPA in 1953 found itself in a unenviable state – whereas it needed 17,569 hand-held grenade launchers it actually had only 11,400 pcs of different models and calibers (44-mm M49, 60-mm M9, 90-mm M20).

In 1952, the Infantry Department sent requests to the Belgrade Military-Technical Institute and Valjevo Krusik enterprise for development of new hand-held grenade launchers and new grenades, as well as for preparation of prototype technical documentation and feasibility study for commercial production of such weapons at the Crvena Zastava factory.

Three solutions had been presented to the YPA Infantry Department board. The first solution based on the simplified Mesicek design was assessed after detailed tests positively. Zastava had prepared the technical documentation, produced “ the zero” lot and started preparing for commercial production. Meanwhile, it was established that the said solution suffers the same production and operation (complex design) drawbacks as the earlier M49 grenade launcher. The Infantry Department recommended to the Kragujevac enterprise to prepare pilot production of other grenade launcher version that would have the cartridge feed mechanism designed as a revolving cylinder for six cartridges. Soon it was proved that such solution failed to neet the required specifications. So, the YPA rejected the overdesigns of the multishot grenade launcher.

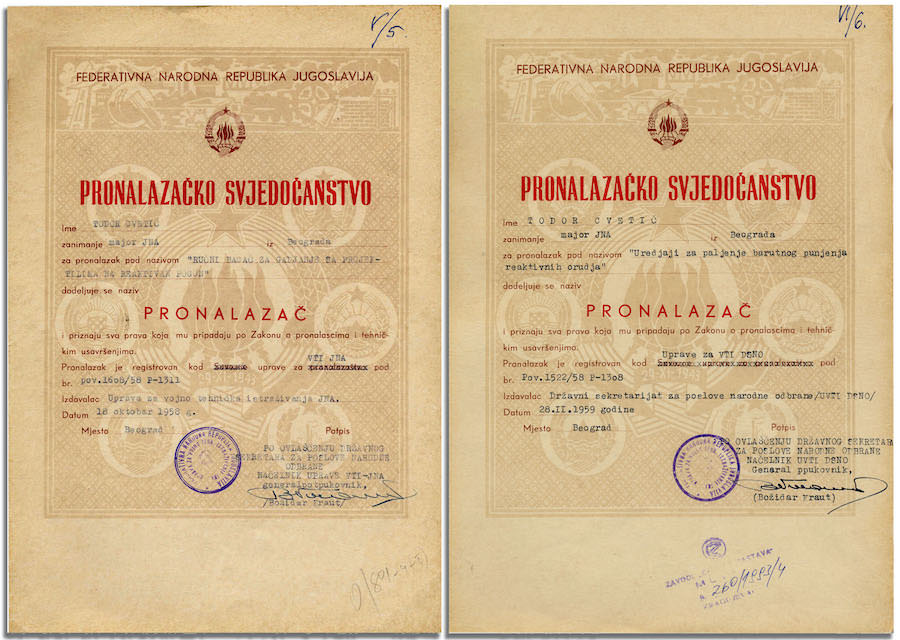

Finallty, the board had decided to examine the design solution proposed by Captain Todor Cvetic of “Arms Institute”. The Cvetic’s idea was to use 93 grams of nitrocellulose smokeless powder as a propellant, and to shift the primer to the grenade tail unit (to increase the muzzle velocity and facilitate preparation for firing). The new grenade had two ignition primers in its tail fin section mounted on its opposite sides at the fin level (to provide for accurate alignment of each ignition primer with the firing pin axis, and rotation of the grenade through 180 degrees if one of the ignition primers fails). The grenade had fins unfolded in flight.

These four flexible metal fins were arranged in the grenade tail unit. To arm the grenade launcher, the grenade was loaded tailfirst through the muzzle with its fins folded into the grooves of the tail unit. The 90-mm overcaliber HEAT warhead was provided with unsafe time/impact fuze UTI M57 (later with time/inertial action fuze UTI M61). The propelling (launching) charge of nitrocellulose powder was placed together with the gunpowder charge and sand batch (sand resistance was used to boost the gas pressure) inside the cardboard case. The firing mechanism was designed on the double action principle to be always ready for firing. As the trigger was squeezed, the firing pin was initially armed and then hit the fuze primer to ignite the gunpowder and nitrocellulose propelling (launching) charge through the hole. This solution provided a high rate of fire (4 rounds per minute), high muzzle velocity of the grenade (Vo = 147 mps), effective target engagement range (200 m – stationary targets, 400 m – moving targets) and high warhead penetration (270 – 300 mm). This weapon of 8200 g heavy had a barrel (960 mm long and 44 mm in caliber), metal sight, optical sight ON M59, bipod, shoulder piece and shoulder sling attachments welded to the barrel.

After different tests the Infantry Department appereciated the Cvetic grenade launcher very high. Crvena Zastava in Kragujevac prepared a set of technological documentation for the commercial production, and in 1956 it produced a pilot lot of 15 grenade launchers. The pilot grenade launchers run a serias of trials and again were highly appreciated. The “zero” lot of 50 pcs was produced in 1958 and sent to operational trials that also confirmed all required combat characteristics. Finally, the Cvetic grenade launcher, coded “RB 44 mm M57”, was accepted for service in the YPA and commercially produced. By 1966, when “the stagnation period” started, Crvena Zastava had produced 26,000 grenade launchers of this design.

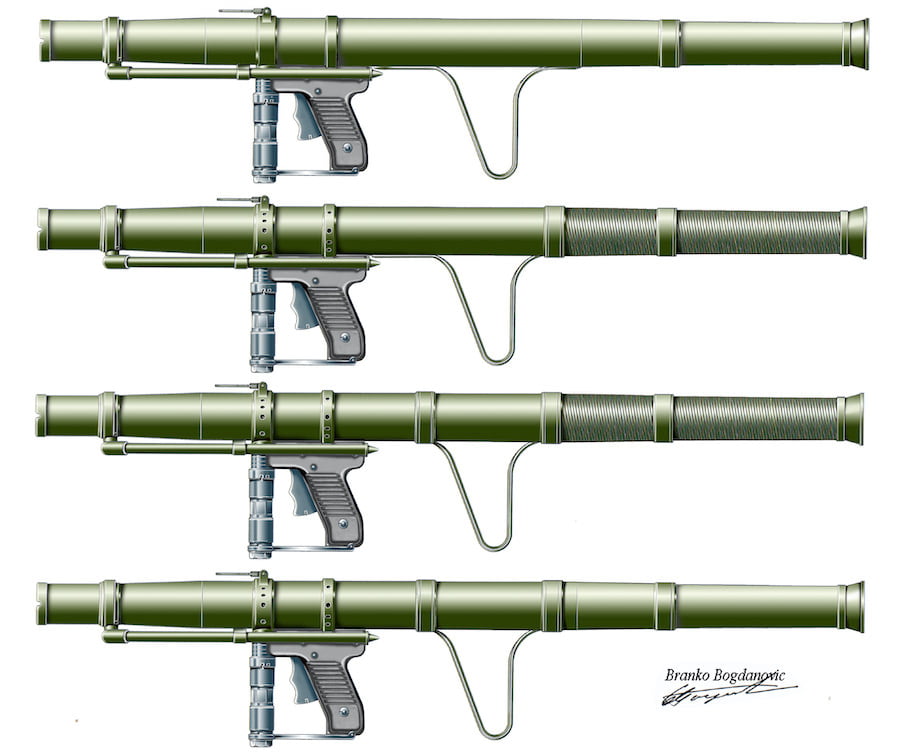

Earlier, in 1964, during a routine inspection two cracks were noticed – in the barrel tube rear section and in the spot where the sling attachment was soldered to the barrel. These cracks were caused by inadequate factory welding. Zastava was to rectify the faults to meet the safety requirements. One of the repair solutions provided for spooling the reinforcing 1.5-mm Zn-coated steel wire on the the barrel rear sections of the grenade launchers in use or even mounting new rings for the shoulder piece and sling attachments (so called “repaired RB”). The grenade launchers of the new series were radically modified – the barrel tube rear section wall was thicken, the shoulder piece and slign attachments were mounted on the rings instead of just welding them to the tube (RB M57A1). The final version of the weapon, A57A2, had a thicker barrel tube rear section wall, rings to mount the shoulder piece, and locating dimples for slign attachment rings.

Within the period from 1965 till April 1, 1967, Zastava produced 4331 modified grenade launchers RB M57A2, and planned to produce additional 12,600 pcs. By 1970, the Kragujevac factory had produced totally 47.751 M57s of all versions. This weapon was one of the most successful Yugoslav national designs, and remained in service for fifty years. Besides, RB M57A2 was the last hand-held AT grenade launcher produced by Zastava. It was still used in the war of 1992-1999 in Yugoslavia yet the troops were already armed with more sophisticated rocket-ropellant grenade launchers of the national and foreign origin.